Our 1,000th Mash

The Batchers of Litchfield Distillery celebrated a milestone today when we began our 1,000th mash. It was a pretty typical day for us, but we captured parts of the process for posterity’s sake. Thank you to all of our customers and retail and distribution partners for your amazing support. We wouldn’t be celebrating this milestone today without your Spirit of Hard Work!

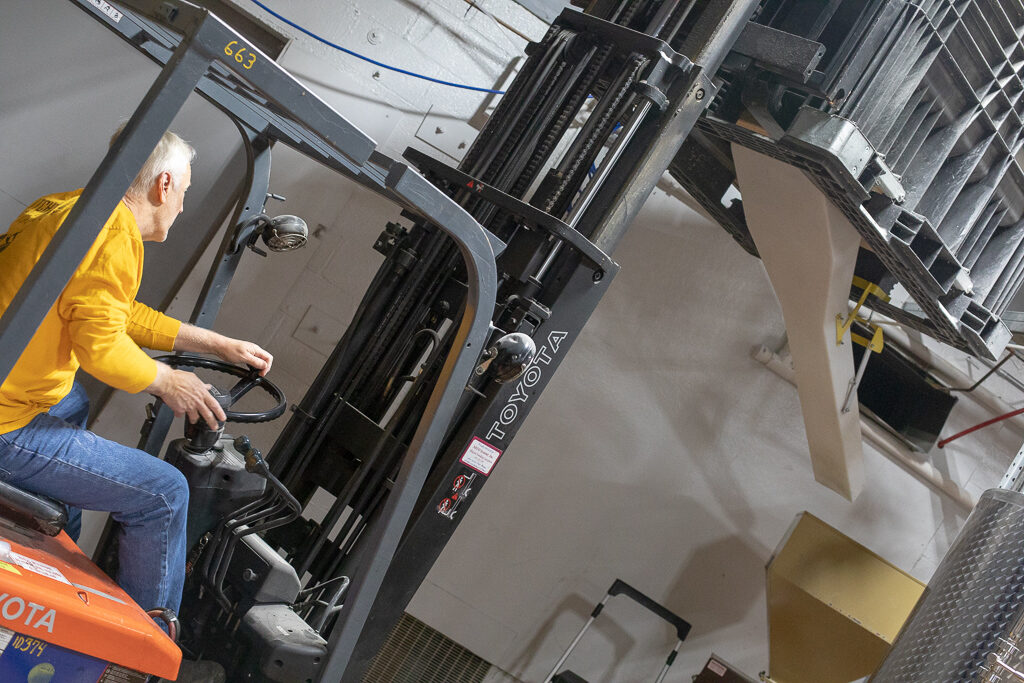

David gets ready to kick off the mash by aligning the fork lift with our grain mill. Of course, David is fully trained in using this large piece of machinery. We also have all of the appropriate signage around the warehouse, such as signal warning people about the nearby fork lift, and the use of heavy machinery. This is the only way it would be safe to use fork lifts to move our grain. If you are needing the use of a fork lift, get the latest here on health and safety signage before committing yourself. Staff safety comes before anything else here.

The grain bin is lifted above the mill so the grains can be gravity fed and ground to our specs.

The grains fill the mill.

Batchers David and Naomi wait for the milled grain and water to fill the mash tun.

The heat and agitation in the mash tun convert the starches in crushed grains into sugars that are needed for distillation

Naomi checks the ph level.

When we’re complete, we wash the mash tun down and prepare for Mash #1,001. #SpiritOfHardWork

If you want to learn more about our entire Farm-to-Bottle-to-Farm distilling process, join us for a free tour and tasting! You reserve a space HERE.